Plastic pressed parts made of PTFE - new ways to better products

PTFE press processing opens up new possibilities for designers.

You can benefit from our experience as PTFE experts and gain a leading position through professionalism and specific know-how.

Due to its very high melt viscosity, PTFE cannot – like most thermoplastic materials – be processed into semi-finished or finished parts by casting, injection molding or transfer molding. Because of its high molecular weight of approximately 10 million g / mol. PTFE forms extremely long molecular chains, which means that the material remains a gel even when the melting temperature of approximately 327 °C is reached.

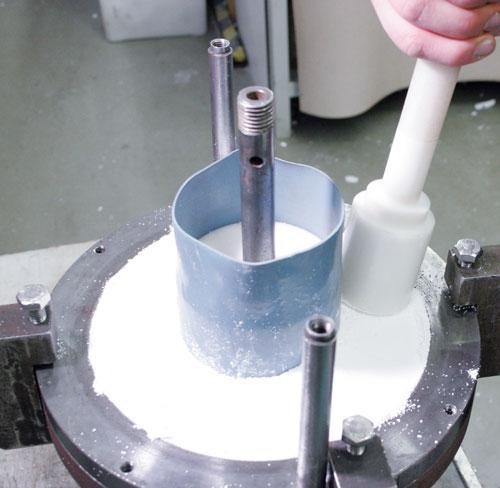

The manufacturers supply the raw material in the form of low-flowing or free-flowing powder. The bulk density for low-flowing powder is around 300 – 500 g / l, for free-flowing powder around 700 – 950 g / l. Homogeneous PTFE material can be achieved by compression to around 2,100 g / l. Depending on the powder type, this corresponds to a compression ratio of 2.2: 1 to 7: 1. The compression must take place so slowly that the air contained between the powder particles can escape completely. This can be achieved with high specific pressures of 12-90 MPa. This requires tools that can withstand these enormous pressures.

Most of these molds are made of high quality steel. Even a relatively small expansion of the mold can lead to shearing and cracks in the material during the pressing process. The result is often a partial or total loss of the blank. At Beichler & Grünenwald, such failures are minimized by a special geometry and construction of the molds.

In static pressing, PTFE granulate is compressed into simple molded parts in press molds with hydraulic pressure. These blanks are sintered in the furnace using precisely defined sintering programs. The isostatic pressed blanks are sintered in the same way. Before that, however, the PTFE granulate is placed in tailor-made tools – very close to the contour of the finished part – and pressure is applied on all sides. For finished parts with extremely different dimensions, this is the most efficient way of processing PTFE.

PTFE powders are usually compressed using hydraulic presses that are specially adapted to the compression criteria of the material. After the compression process into different shapes such as plates, cylinders, hollow rods or special shapes, the blanks are still very fragile. In the subsequent sintering process in special sintering furnaces does the molded material acquire the typical PTFE properties.

The blanks are usually sintered at approx. 375 ° C. To ensure that heat-related stresses do not cause cracks or voids in the fragile blank, special programs control and regulate the warming-up, constant temperature and cooling of the blank. Depending on the molded part, this process takes 12 to 90 hours.

After sintering, the blanks generally go through further machining steps by turning or milling. The required dimensions and tolerances are conveyed to the resulting component. The volume of the blanks shrinks between 2.5 and 5% during the sintering process – depending on the powder type. The resulting tolerances are too crude for most requirements, so this post-processing step is almost always necessary.

The processes described also apply to PTFE with fillers. The fillers ensure that the component is properly equipped and reinforced. Beichler & Grünenwald advises you with experience and know-how on the selection of the ideal raw material mixture, manufactures molds according to your requirements and accompanies your product to the finished pressed semi-finished or finished part.

Interesting facts about hydraulic and isostatic pressing processes.

Interesting facts about hydraulic and isostatic pressing processes. Semi-finished PTFE products are manufactured either by hydraulic or isostatic press processing. The difference between the two processes is the direction in which the blanks are produced. The blanks of both pressing processes are sintered in special furnaces. In hydraulic pressing, PTFE is hydraulic compressed in molds in the axial direction to form simple molded parts, while in isostatic pressing, the material is pressed from all sides with uniform pressure using custom-made tools. Due to the extremely homogeneous material structure, the isostatic pressing process optimizes the already excellent properties of PTFE. Another advantage is that even casings with complex contours can be lined with PTFE. There are limits to the static pressing process in this term. Beichler & Grünenwald calculates and designs tools for customer-specific component production that enable efficient material savings of up to 90%. In addition, special processes are used to prepare surfaces to be coated in such a way that an absolute, vacuum-tight bond is achieved.